- Home

- Applications

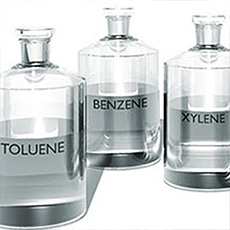

- Btx Benzene Toluene Xylene

BTX (Benzene, Toluene and Xylene)

Purify benzene, toluene, and xylene (BTX) from aromatic streams found in refineries or petrochemicals, such as catalytic reformate or pyrolysis gasoline. It uses liquid-liquid extraction, which is cost-effective in both initial investment and ongoing operations. This method is straightforward to operate, works with various feedstocks, and delivers efficient solvent performance.

Related technologies

LiquiSep technology has been implemented specifically to help separate emulsions that are not separable by conventional coalescers. Conventional coalescers are unable to provide the degree clarity associated with LiquiSep technology due to the inability to capture and remove the most penetrating droplets that cause carry-over. LiquiSep can separate these dispersed and emulsified droplets from the hydrocarbon to practically non-detectable levels.

Compared to conventional cartridge filters, COMPAX saves you money by lowering operating costs and reducing disposal costs. When comparing filters with the same efficiencies or Beta ratings, nothing outperforms the cost/performance value achieved with COMPAX.

The ProcessOR is a superior separator vessel often used for particle/liquid filtration or separation. It is available to be delivered as a self-contained skid (pictured) or a stand-alone vessel. It is also available custom sized as a capital sale or as a turn-key rental, which is often available within days of the received order.

EXTRACTIVE SEPARATIONS - POLAREX

Polarex, US Patent 8425663, an extractive separations technology provides gas processors, chemical manufacturers, and refiners dramatically improved separation of entrained and dissolved contaminants. It is designed to replace conventional water wash and solvent scrubbing towers.