- Home

- Technologies

- Polarex

Polarex extraction systems have been developed utilizing Pentair Polarex Technology to create a single-stage, high-efficiency, structured contactor/separator. Saving end-users capital while increasing process reliability, greater operability and product quality.

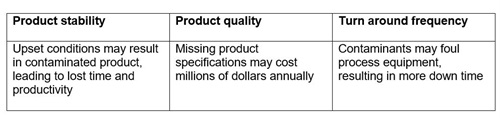

CHALLENGES

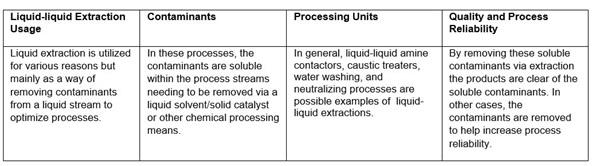

You can tackle these challenges to extract soluble contaminants in midstream, downstream and petrochemical applications with technologies for liquid-liquid extraction.

Benefits

Instead of conventional system:

- Higher mass transfer rate

- Smaller, modular system design

- Higher equilibrium efficiency for each stage (Murphee efficiency 90-95%)

- Reduced solvent usage

- Fewer extraction stages to achieve desired extraction

- Specialized Pentair Media to minimize solvent carry-over (removal of sub-micron size droplets)

- High turndown ratio

- Reduced CAPEX and OPEX

- Fewer operational issues (i.e. flooding, etc.)

-

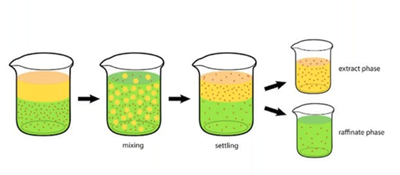

FUNCTIONAL DESCRIPTION

-

Conventional Systems

Trayed Columns & Packed Columns are conventional approaches to remove dissolved contaminants that utilize washing the hydrocarbon with water.

Disadvantages

- High solvent losses

- Low operating window

- Low stage efficiencies

- Bigger equipment size

- Higher solvent re-circulation rates

- Higher capital cost

- Poor separations of process and solvent streams

-

FIELDS OF APPLICATION

-

- Caustic recovery

- Amine recovery from Liquefied petroleum gas (LPG)

- Amine treating Natural Gas Liquids (NGL)

- Methanol removal

- Chloride salt removal from Butane

Watch what the Pentair Polarex Technology has to offer

Explore the Pentair Polarex Technology and how it works in midstream, downstream and petrochemical applications.

RELATED APPLICATIONS

There are two basic steps to the treatment of natural gas liquids in the natural gas stream. First, the liquids must be extracted from the natural gas. Second, these NGLs must be separated themselves.

The key aspects of a caustic treating system pertain to the degree of contact between the caustic and hydrocarbon to facilitate the mass transfer.

Eliminate hydrocarbons in Quench Water system, minimize fouling, provide greater system reliability, lower maintenance, lower energy costs.

BTX (BENZENE, TOLUENE AND XYLENE)

Purify benzene, toluene, and xylene (BTX) from refinery or petrochemical aromatics streams such as catalytic reformate or pyrolysis gasoline. This liquid-liquid extraction processes offers lower capital and operating costs, simplicity of operation, range of feedstock, and solvent performance.

Reactor products can contain gelatinous, deformable solids form in coating formulation. Batch Process: Limited reactor turn-over (constrained through-put) due to long filtration process. Reduce operating costs and batch cycle time, double capacity and increase online life.

Silicones are inert, synthetic compounds with a variety of forms and uses. Typically heat-resistant and rubber-like, they are used in sealants, adhesives, lubricants, medical applications, cookware, and insulation.