- Home

- Technologies

- HRT

Hydrocarbon Recovery Technology (HRT) provides petroleum producers, refiners, and gas processors with dramatically improved solids control and hydrocarbon recovery from process water streams.

HRT affords proven performance while eliminating the need for expensive excess processing, chemical additives, and storage tank capacity. With hydrocarbon recovery efficiencies of 99.98%, HRT produces a sellable product, balancing or even outweighing operating costs and capital investment.

Benefits

- Operational flexibility

- Reduction of lost energy

- Savings on chemical additives

- Lower maintenance costs associated with fouling

- Elimination of excursions

-

FUNCTIONAL DESCRIPTION

-

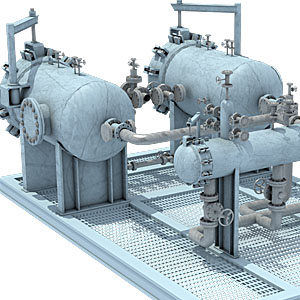

Scalable and Modular Design

HRT’s robust design is scalable and modular for both new capital projects as well as placement in existing operating units.

Why HRT is Better than Conventional Solutions

Most process water systems experience either periodic or continuous hydrocarbon and/or solids upsets, leading to:

- Diminished capacity

- Loss of valuable product

- Fouling of heat transfer surfaces and equipment

- In extreme cases, shutdown due to environmental emissions

RELATED APPLICATIONS

PRODUCED WATER MANAGEMENT - OFFSHORE

A combination of factors in recent years has led to increased attention to water management in the oil and gas industry.

PRODUCED WATER - SALT WATER DISPOSAL

A combination of factors in recent years has led to increased attention to water management in the oil and gas industry.

There are a number of factors that affect the capacity and operation of a typical amine system. Solid or liquid contaminants in the system may cause foaming. The presence of foaming is typically addressed by the addition of expensive antifoam chemicals and/or by reducing the operating capacity of the amine system.

Glycol dehydration is a liquid desiccant system for the removal of water from natural gas and natural gas liquids (NGL).

PRODUCED WATER MANAGEMENT - ONSHORE

A combination of factors in recent years has led to increased attention to water management in the oil and gas industry.

Hydrocarbons in the sour water system are typically present on a continuous basis at up to 10,000 ppm and during upsets to levels greater than 50,000 ppm.

Proper fluid and proppant placement are critical to a successful propped fracture stimulation treatment.

Until recently, the Liquefied Natural Gas (LNG) market was a relatively small part of the gas processing world. The market has experienced a transformation fueled by the discovery of vast reserves in North America, Asia’s robust economic growth, larger populations, and the demand for cleaner energy.